INVENTEC Solder Paste ECOREL™ FREE 305-16LVD

* Benefits

No clean, lead-free solder paste developed with the reliable chemistry of the ECOREL™ range. Passed BONO Test.

|

PERFORMANCE |

·

Low

voiding to offer great heat dissipation ·

Very

good wetting on all surface finishes, including OSP ·

Transparent

colorless residue, even after multiple reflow cycles |

|

COST |

·

Good

first pass yield testability in ICT ·

Increase

lifetime and reliability of your product, hence reduces risk of premature

failures. |

|

HSE |

·

No

halogen ·

Lead

free |

* Features

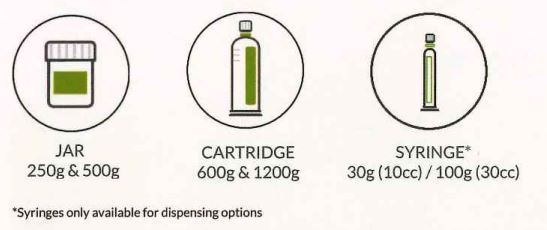

STANDARD OPTIONS

|

SPECIFICATIONS |

ECOREL 305-16LVD

88.0T4 |

ECOREL 305-16LVD

88.5T4 |

ECOREL 305-16LVD

88.5T5 |

|

Alloy |

Sn96,5Ag3Cu0,5 |

Sn96,5Ag3Cu0,5 |

Sn96,5Ag3Cu0,5 |

|

Melting

point (oC/oF) |

217 / 422 |

217 / 422 |

217 / 422 |

|

Metal

content (%) |

88 |

88.5 |

88.5 |

|

Post

reflow residues |

Approximately 5% by w/w |

Approximately 5% by w/w |

Approximately 5% by w/w |

|

Halogen

content |

No Halogen |

No Halogen |

No Halogen |

|

Powder

size |

20 – 38 microns / Type 4 |

20 – 38 microns / Type 4 |

15-25 microns / Type 5 |

|

Spiral

pump* Viscosity (Pa.s 25oC) |

Typical 135 |

Typical 135 |

Typical 155 |

*The

equipment used to test spiral pump viscosity is Malcom at a 10 rpm rotation

speed.

DISPENSING OPTIONS

|

SPECIFICATIONS |

ECOREL 305-16LVD

85.0T5 |

|

Alloy |

Sn96,5Ag3Cu0,5 |

|

Melting

point (oC/oF) |

217 / 422 |

|

Metal

content (%) |

85 |

|

Post

reflow residues |

Approximately 5% by w/w |

|

Halogen

content |

No Halogen |

|

Powder

size |

15 – 25 microns / Type 5 |

|

Spiral

pump* Viscosity (Pa.s 25oC) |

Typical 65 |