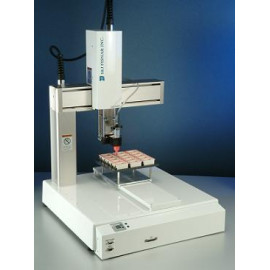

A powerful and optimum sized benchtop robot with a working area of 19.68"x19.68" (500x500mm) and extra Z reach of 5.90" (150mm). Ideal for large non contiguous structures and for larger dispensing equipment or apparatus. The F4500N is suitable for plasma treatment applications prior to dispensing. Programming is carried out by a teach-pendant (included) using the industry's leading dispensing software that walks the user through step-by-step instructions to create a sophisticated dispensing operation in minutes.

Features

- Dispensing area of 19.68" x 19.68" (500mm x 500mm)

- High resolution 0.001mm

- On board 100 programs, 400,000 point memory capacity, 4,000 points per program

- Performs continuous path and point-to-point motions

- Quick fluid-purge button located on front panel

- Software tip alignment routine for quick program offsets when changing dispensing tips

- Step-and-repeat functions - program one object only for multiple identical objects

- Ideal for form-in-place gaskets, adhesives, potting, coating and filling

- Available without Teach Pendant for multiple installations

- USB connector allows system updates and program interchange between robots

Models

| F4500N | Robot 3-axes 110/220V CE |

F4500N desktop robot specifications

| XYZ Robot Working Area/ mm | 500 / 500 / 150 |

| Worktable Load/Tool | 10kg / 5kg |

| Speed PTP XY& Z (mm/sec) | 800 / 320 |

| Repeatability | +/- 0.02mm/ Axis |

| Resolution | 0.001mm/Axis |

| Data Memory | 100 programs, 4000 points/program |

| Drive System/Stepping Motor | 3-Phase |

| Motion Control | PTP & CP |

| Teaching Method | Teach Pendant |

| I/O Signals | 8 Inputs / 8 Outputs |

| External Interface | USB / RS232 |

| Power Supply | AC 95-132V, AC 180-250V |

| Dimensions (WxDxH) mm | 685 x 698 x 746mm |

| Weight | 102 lbs (46 kg) |