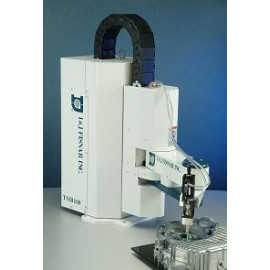

A 4 axes high-speed industrial SCARA robot ideal for high volume and large area dispensing applications requiring greater flexibility for automated manufacturing environments, including conveyors and work cells. Can also be used for pick & place applications.

Features

- Highly rigid frame structure

- Ideal for form-in-place gaskets, adhesives, potting, coating, filling and pick & place procedures

- Positioning repeatability 0.020mm

- Performs continuous path and point-to-point motions

- AC servo motors

- Software tip alignment routine for quick program offsets when changing dispensing tips

- Digital servo controlled motors

- Multiple I/O communications

- High speed movement up to 5000mm/sec

Model

| F20004N | 4-Axis SCARA Robot 220v |

Specifications

| Rated/Max Payload (J1+J2 arm) | 2/7 kg |

| Arm Length | 300 + 300 mm |

| Repeatability:J1 + J2 arm, J3, J4 | +/-0.03 mm, +/-0.02 mm, +/-0.03° |

| Operating range | +/-125°, +/-125°, 200 mm, +/-360° |

| Max Speed (No Load) | 5.6 m/s, 1 m/s, 720°/s |

| Allowable inertia of J4 | 0.003 kgf.m.s2 |

| Data Memory Capacity | 100 programs, 1000 points/program |

| Drive system | Full Digital AC servo |

| Operation system | Point-To-Point, Continuous Path |

| Interpolation | All axes |

| Teaching method | Teach Pendant, PC |

| PLC: | 10 programs, 1000 steps/program |

| I/O signals | System I/O 24/6, User I/O 32/32 |

| External interface | RS232C |

| Wiring & piping to tool | 4 air pipes (6mm), 15 wires for signals |

| Power supply | 1ø AC220V |

| Working temperature | 0 - 40°C |

| Relative humidity | 20 - 90% |

| Dimensions (WxDxH) mm | 240x828x834 |

| Manipulator Weight | 37kg |

| Controller Weight | 10kg |