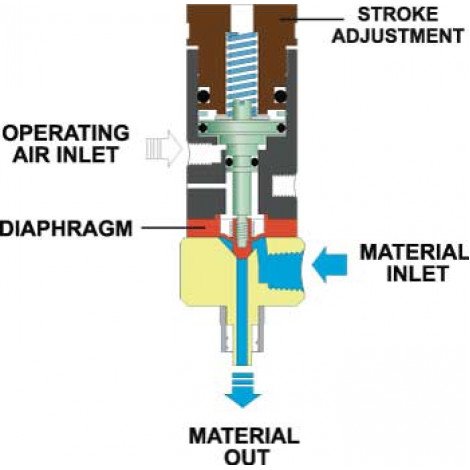

The VD510 is a diaphragm valve designed for precise flow control of low to medium viscosity materials. The diaphragm separates the wetted parts from the moving parts and, therefore, the valve is ideal for dispensing cyanoacrylates, reagents, electrolytes, glues, solvents, paints, alcohol and other volatile substances. The model DSP501N is a suitable controller for the VD510 valve. 3-Way Valve Operation When air pressure is applied to the VD510 valve, the valve will open and the material will be dispensed. At the end of the dispense cycle a spring assists the diaphragm to return quickly to its closed state for immediate shut-off. Shot sizes may be fine tuned by turning the stroke adjustment at the top of the valve.

Features

- Stroke adjustment to fine tune shot size

- Separated wetted parts

- Suitable for robot integration

- Suitable for anaerobic fluids

Model

| VD510 | Diaphragm valve |

| VD510-SS | Stainless steel diaphragm valve |

| VD510-UV | UV suitable diaphragm valve |

VD510 Specifications:

| Operating air pressure | 60-85psi (4.1 - 5.9 bar) |

| Fluid delivery pressure | 71psi (4.9 bar) |

| Flow rate | Max. 0.3 l/min |

| Minimum shot size | 0.001cc (material dependant) |

|

Driving part materials |

|

| Body | AL (hard coated, black) |

| Piston | SUS303 |

| Piston seal | NBR |

| Wetted part materials | UHMW-PE |

| Connecting Ports | |

| Operating air input | M5xP0.8 |

| Material inlet | 1/8" NPT |

| Material outlet | Luer lock |

| Weight | 76g |