The 790HP-LF series high-pressure dispense valve is an economic solution when dispensing high viscosity materials such as silicones, RTV, sealant and grease. The 790HP-LF provides a snap-release shut off after dispensing, resulting in a suck-back at the fluid outlet, preventing any drip or post extrusion.

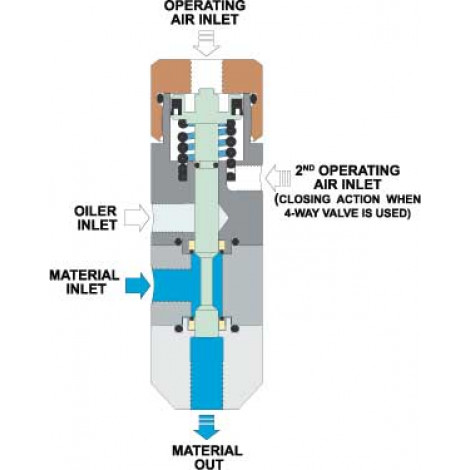

3-Way & 4-Way Valve Operation

The 790HP-LF is a balanced type "on/off" segmented high-pressure spool valve. Applying a minimum of 50 psi to the air inlet will force the spool forward, under tension from an internal return spring, dispensing the material.

Releasing the air pressure results in the internal spring snapping back into position and closing the valve.

790HP-LF valves can be used with a 3-way air valve controller DSP501N. Should the operation require automation, a faster closing action can be achieved using the 4-way valve controller VC1195N.

Features

- High-pressure fluid input up to 2500 psi

- Suitable for very high viscosity fluids

- Replaceable seals

Model

| 790HP-LF | High-pressure valve aluminum |

| 790HPSS-LF | High-pressure valve stainless steel |

790HP-LF Specifications:

| Material input pressure | Max. 2500psi (172.4 bar) |

| Air pressure required | Min. 60psi (4.1 bar) |

| Valve body | |

| 790HP-LF | Aluminum |

| 790HPSS-LF | Stainless Steel |

| Connecting Ports | |

| Operating air input | 1/4" NPT |

| Material inlet | 1/4" NPT |

| Material outlet | 1/4" NPT |

| Seals | O-ring - viton, seats are glass filled Teflon |