The VMP30H is a multipurpose, mini-poppet pneumatic valve designed for dispensing low to mid-high viscosity materials, such as silicone, RTV, epoxy, rubber adhesive, grease and filled materials. The poppet design minimizes surface area and friction between the valve piston and the material, making it ideal for filled materials and extending the life of the valve seals.

A diaphragm located between driving parts and wetted parts increases the valve life and reduces valve maintenance.

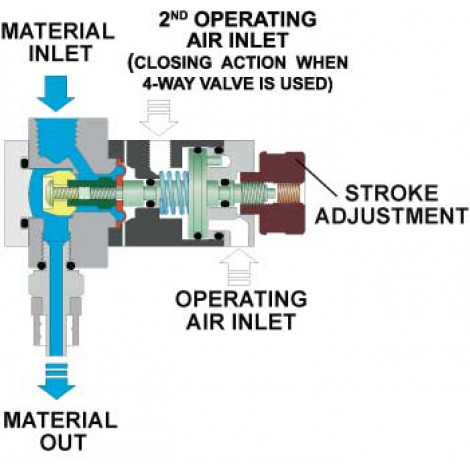

3-Way & 4-Way Valve Operation

When air pressure is applied to the valve, the valve seat will open and the material will be dispensed. Shot sizes may be fine tuned by turning the control knob at the top of the valve.

The VMP30H valve has a suck-back effect, which draws material back into the fluid body at the end of the dispensing cycle. This eliminates lumping at the end of the needle after dispensing.

The model DSP501N is a suitable controller for the VMP30H valve. For faster actuation, the 4-way VC1195N valve controller is recommended.

Features

- Stroke adjustment to fine tune shot size

- "Suck-back" effect

- Seperated wetted parts

- Suitable for filled materials

Model

| VMP30H | Mini Poppet valve |

MV-0180LF Specifications:

| Operating air pressure | 50-85psi (3.4 - 5.9 bar) |

| Fluid delivery pressure | Max. 85psi (5.9 bar) |

| Flow rate | Max. 1.2 l/min |

| Minimum shot size | 0.01cc |

| Driving part materials | |

| Body | AL (hard anodizing, black) |

| Piston | SUS303 |

| Piston Seal | NBR |

| Wetted Part Materials | |

| Cahmber, CAP | SUS303 |

| Diaphragm, valve seat | UHMW-PE |

| O-ring (CAP) | Viton |

| **Option** | The Chamber, CAP, and wetted parts can be replaced with SUS303, AL, PPEK, Acteal. |

|

Connecting ports |

|

| Operating air input | M5xP0.8 |

| Material inlet | 1/8" NPT |

| Material outlet | Luer lock |

| Weight | 162g |