SV2000N Adjustable No - clog Spray Valve

- RM0

- Availability:In Stock

- Brand: Fisnar

- Product Code: SV2000N

Fisnar spray valves provide close tolerance spray dispensing of fluids up to 1000 cps, including urethanes, flux and paints. The material is fed from a pressure reservoir. Each valve is actuated by air pressure sequenced by a controller. The operating air pressure opens a needle valve allowing material to flow; a separate air line creates pressure in the air cap, atomizing the fluid.

Operation

The valves are adjustable by turning the stroke-adjust control at the rear of the valve; this will tune the spray pattern.

Coating and flow rate are controlled by the fluid pressure, needle stroke, distance from the valve to the work and the duration the valve is open.

Models

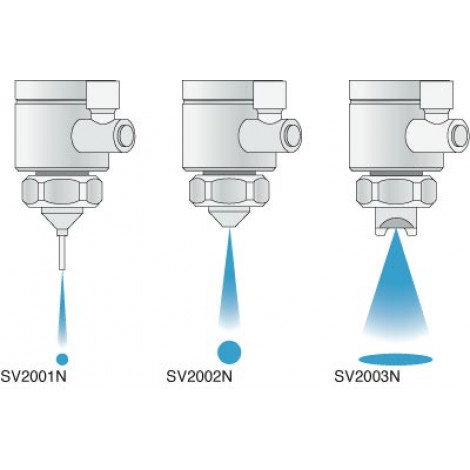

|

SV2001N |

Spray valve fine dot & bead |

|

SV2002N |

Spray valve medium pattern |

|

SV2003N |

Spray valve fan pattern |

SV2000 Specifications:

|

Operating air pressure |

60-80 psi (4.1 - 5.5 bar) |

|

Atomizing air pressure |

1-30 psi |

|

Fluid viscosity range |

up to 1000 cps |

|

Fluid pressure |

0.5mm - Max 1.2kgf/cm² |

|

Operating frequency |

Over 200 cycles/min |

|

Flow rate |

Up to 2.4 l/min |

|

Spray pattern |

Circular (conical spray) |

|

Spray angle at 40mm |

SV2001N - 20º |

|

Operating air inlet |

M5xP0.8 with push-in fitting for Ø4 urethane hose |

|

Atomizing air inlet |

M5xP0.8 with push-in fitting for Ø4 urethane hose |

|

Material inlet |

1/8" NPT |

|

Weight |

8.8 oz. (250gm) |

Sample spray path character:

|

SV2001N: |

min. bead: 3mm, overspray: 0.5mm |

|

SV2002N: |

min. bead: 12mm, overspray: 5mm |

|

SV2003N: |

min. bead: 18mm, overspray: 10mm |